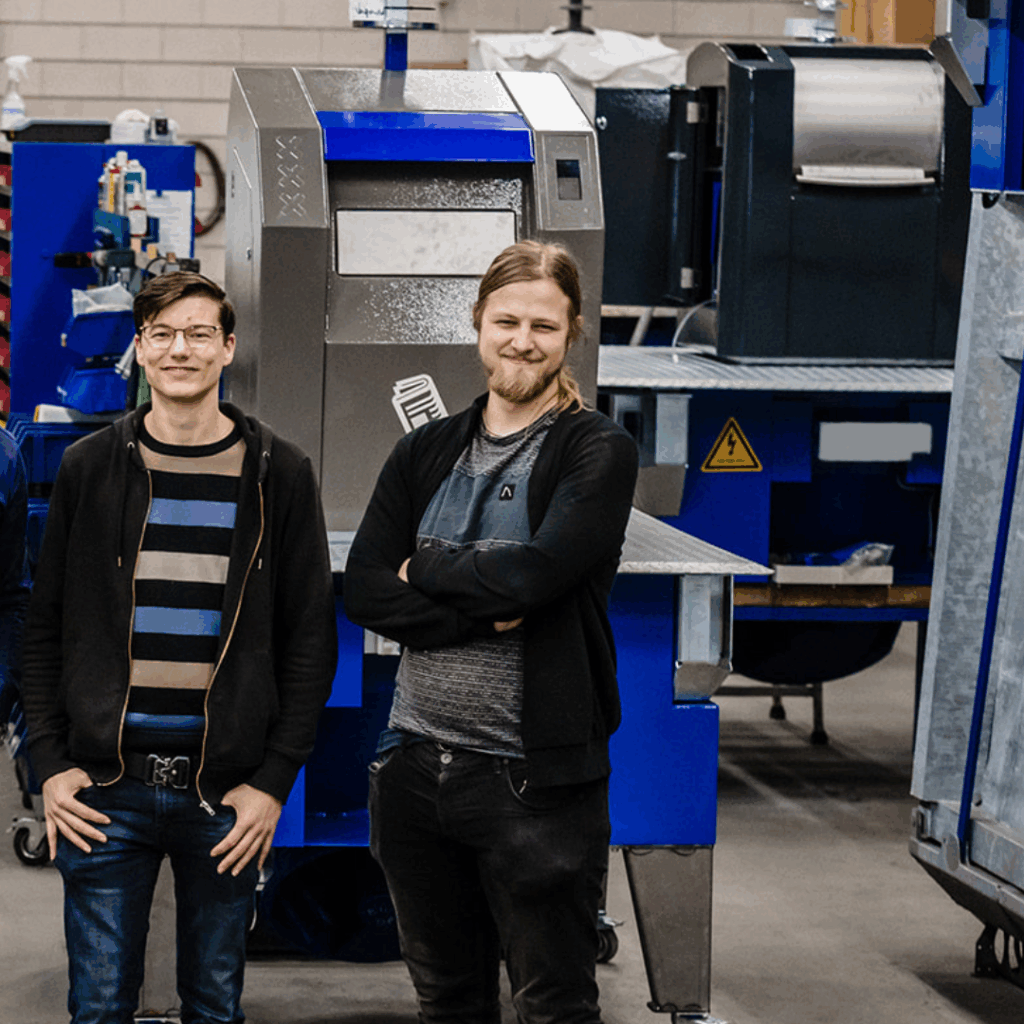

On the train in the morning, Boris often starts his day by learning a bit of Japanese with his headphones on. As a programmer at Sidcon, he has been ensuring since 2023 that our compactors run better and better, and that error messages become increasingly rare.

“My alarm is set for 6 a.m. Then it’s simply a matter of showering, having breakfast and getting out the door as quickly as possible. I usually leave around seven. I travel to work by public transport: first the train and then the bus. To pass the time, I watch a YouTube video or a series. At the moment, I’m learning Japanese, which is also a great train activity.”

“When I arrive at the office, I naturally start by opening my emails. I check what has come in and whether anyone urgently needs my help. Then I open all the programmes I expect to need that day, and get to work.”

“My days are quite varied, but a large part of my work is programming, building or expanding new features. And if an error is found in the system, I fix it and test it. I mainly do this in collaboration with our Service & Maintenance team, and occasionally with Production. They receive information from customers or field staff and pass it on to me. Sometimes these issues need to be solved the same day; other times I have a bit more time.”

“The best moment in a workday, and actually in my entire career, is when you have been stuck on something for a long time and it finally works.''

“We are also constantly asking ourselves how we can make the compactor run even better, and what information we want to extract from it. Customers want more and more insight into what the compactor is doing. I work on what information we can obtain from the sensors inside the container and how we display that in the system. Alongside that, we are building a new platform where all of this will soon be available to customers.”

“The best moment in a workday, and actually in my entire career, is when you have been stuck on something for a long time and it finally works. When you start something up and that annoying error message is finally gone. Or when a device finally runs exactly as it should, without any problems. Those moments are such a relief. For me, they are definitely worth celebrating.”

“As the last task of the day, I check my emails once more and make sure all my work is properly documented and saved. If I’m the last one in the department, I close the windows and doors, and of course turn off the lights. And then it’s time for the journey home again.”

“We are also constantly asking ourselves how we can make the compactor run even better, and what information we want to extract from it. Customers want more and more insight into what the compactor is doing. I work on what information we can obtain from the sensors inside the container and how we display that in the system. Alongside that, we are building a new platform where all of this will soon be available to customers.”

“The best moment in a workday, and actually in my entire career, is when you have been stuck on something for a long time and it finally works. When you start something up and that annoying error message is finally gone. Or when a device finally runs exactly as it should, without any problems. Those moments are such a relief. For me, they are definitely worth celebrating.”

“As the last task of the day, I check my emails once more and make sure all my work is properly documented and saved. If I’m the last one in the department, I close the windows and doors, and of course turn off the lights. And then it’s time for the journey home again.”